Robotics has rapidly evolved from science fiction to a tangible and transformative force reshaping industries, daily life, and the very fabric of our future. Whether it’s automating manufacturing processes, assisting in complex surgeries, or exploring distant planets, robots are increasingly integrated into our world. This blog post will delve into the multifaceted world of robotics, exploring its core components, diverse applications, and potential impact on society.

What is Robotics?

Defining Robotics

Robotics is an interdisciplinary field encompassing engineering, computer science, and other sciences that deals with the design, construction, operation, and application of robots. It combines principles from mechanical engineering, electrical engineering, computer programming, and artificial intelligence to create machines capable of performing tasks autonomously or semi-autonomously.

- Key Components of a Robot:

Sensors: Provide robots with information about their environment (e.g., cameras, ultrasonic sensors, force sensors).

Actuators: Enable movement and interaction (e.g., motors, hydraulic systems, pneumatic systems).

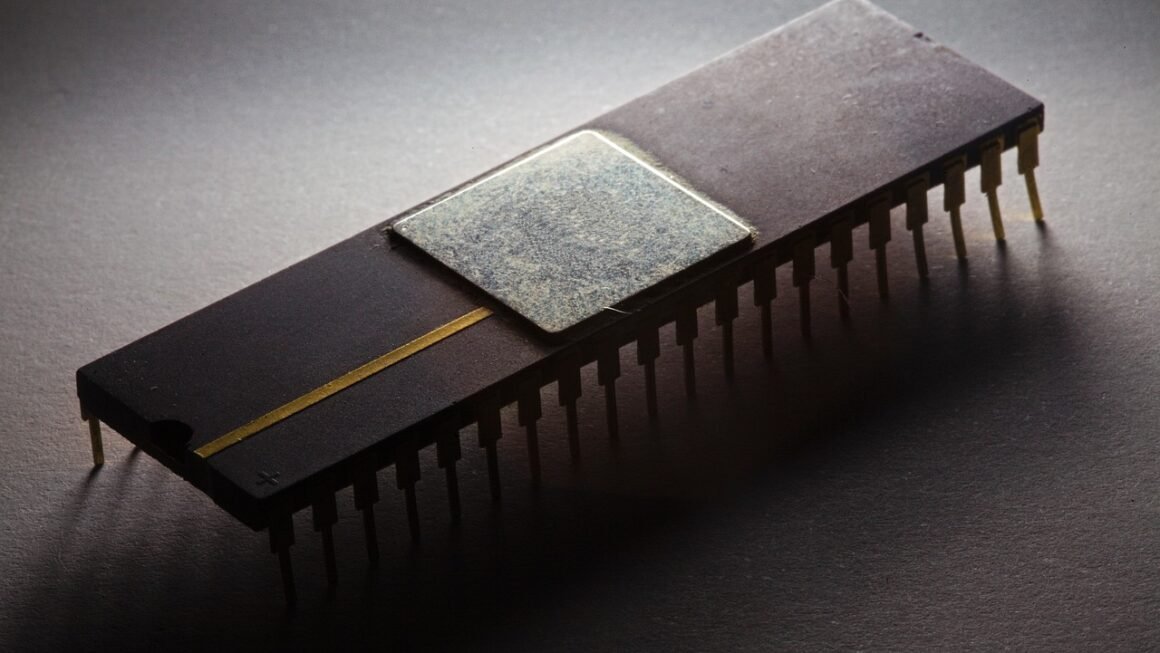

Controllers: Process sensor data and control actuators (e.g., microprocessors, embedded systems).

Power Source: Provides energy for operation (e.g., batteries, electric cords).

Software: Algorithms and programs that define the robot’s behavior.

Types of Robots

Robots come in various shapes and sizes, each designed for specific tasks. Some common types include:

- Industrial Robots: Used for automated manufacturing tasks like welding, painting, and assembly. For example, articulated robots with multiple joints are commonly used on automotive assembly lines.

- Service Robots: Assist humans in various tasks, such as cleaning, delivering goods, or providing security. Think of Roomba vacuum cleaners or automated delivery drones.

- Medical Robots: Used in surgery, rehabilitation, and drug delivery. The da Vinci Surgical System allows surgeons to perform minimally invasive procedures with enhanced precision.

- Exploration Robots: Designed to explore hazardous or inaccessible environments, like Mars rovers or underwater drones.

- Military Robots: Used for surveillance, reconnaissance, and bomb disposal.

- Social Robots: Designed to interact with humans in a social context, such as providing companionship or education.

Applications of Robotics Across Industries

Manufacturing and Automation

Robotics has revolutionized manufacturing by automating repetitive and dangerous tasks. Industrial robots are used for:

- Assembly: Robots can precisely assemble components faster and more accurately than humans.

- Welding: Automated welding systems improve weld quality and reduce labor costs.

- Painting: Robots can apply paint evenly and consistently, reducing waste and improving finish quality.

- Material Handling: Robots can efficiently move materials between workstations, improving workflow.

- Quality Control: Robots equipped with vision systems can inspect products for defects.

- Example: Automotive manufacturers heavily rely on robotic arms to assemble vehicles, weld components, and paint bodies with unmatched speed and precision. This has significantly increased production output while ensuring consistent quality.

Healthcare and Medicine

Robotics is transforming healthcare by improving surgical precision, assisting in rehabilitation, and enhancing patient care.

- Surgical Robots: Enable surgeons to perform complex procedures with greater precision and less invasiveness, leading to faster recovery times.

- Rehabilitation Robots: Assist patients in regaining mobility and strength after injuries or strokes. For instance, exoskeletons can help paralyzed individuals walk.

- Drug Delivery Robots: Precisely deliver medication to targeted areas of the body, minimizing side effects.

- Automated Dispensing Systems: Accurately dispense medications in pharmacies and hospitals, reducing errors and improving efficiency.

- Example: The da Vinci Surgical System allows surgeons to perform minimally invasive surgeries with greater dexterity and control. It provides a 3D high-definition view of the surgical site and allows for smaller incisions, resulting in less pain and faster recovery for patients.

Logistics and Supply Chain

Robotics is streamlining logistics and supply chain operations by automating warehousing, transportation, and delivery.

- Automated Guided Vehicles (AGVs): Transport materials within warehouses and factories.

- Automated Storage and Retrieval Systems (AS/RS): Efficiently store and retrieve items from shelves.

- Sorting and Packing Robots: Quickly and accurately sort and pack products for shipping.

- Delivery Drones: Deliver packages to customers in urban and rural areas.

- Example: Amazon uses thousands of robots in its warehouses to move shelves of products to human pickers, significantly reducing the time it takes to fulfill orders. This increases efficiency and reduces labor costs.

Exploration and Research

Robots are essential for exploring environments that are dangerous or inaccessible to humans, such as space, underwater, and disaster zones.

- Space Exploration Rovers: Explore planets and moons, collecting data and samples. The Mars rovers, like Curiosity and Perseverance, are prime examples.

- Underwater Drones (ROVs): Explore the ocean depths, inspecting pipelines and conducting research.

- Search and Rescue Robots: Assist in locating and rescuing victims in disaster areas.

- Hazardous Environment Robots: Inspect and maintain equipment in nuclear power plants and chemical facilities.

- Example: The Perseverance rover, currently on Mars, is searching for signs of past microbial life and collecting samples for future return to Earth. These robots endure harsh conditions and perform complex tasks autonomously.

The Impact of Robotics on Society

Economic Impact

Robotics has a significant economic impact by increasing productivity, reducing costs, and creating new jobs.

- Increased Productivity: Robots can work 24/7 without breaks, leading to higher output.

- Reduced Costs: Automation can reduce labor costs and improve efficiency.

- Job Creation: While some jobs may be displaced by automation, new jobs are created in robotics design, manufacturing, and maintenance.

- Economic Growth: Robotics can drive economic growth by increasing competitiveness and innovation.

- Data: According to a report by the International Federation of Robotics (IFR), the global robot density in the manufacturing industry reached a new high of 141 robots per 10,000 employees in 2021. This indicates a growing adoption of robotics in manufacturing worldwide.

Ethical Considerations

The increasing use of robotics raises ethical concerns that need to be addressed.

- Job Displacement: Automation may lead to job losses in certain industries, requiring retraining and workforce development programs.

- Bias in AI: Robots powered by AI can perpetuate biases present in the data they are trained on, leading to unfair or discriminatory outcomes.

- Autonomous Weapons: The development of autonomous weapons systems raises concerns about accountability and the potential for unintended consequences.

- Privacy and Security: Robots equipped with sensors and cameras can collect data that may compromise privacy and security.

The Future of Robotics

The future of robotics is likely to see even greater integration of robots into our lives, with advancements in artificial intelligence, machine learning, and sensor technology driving innovation. Key trends include:

- Collaborative Robots (Cobots): Robots designed to work safely alongside humans.

- Artificial Intelligence (AI): AI is enabling robots to perform more complex tasks and make autonomous decisions.

- Machine Learning (ML): ML is allowing robots to learn from data and improve their performance over time.

- Human-Robot Interaction (HRI): Improving the way humans and robots interact is crucial for widespread adoption.

Getting Started with Robotics

Educational Resources

There are numerous educational resources available for those interested in learning about robotics.

- Online Courses: Platforms like Coursera, edX, and Udacity offer courses on robotics, AI, and related topics.

- University Programs: Many universities offer undergraduate and graduate programs in robotics and related fields.

- Robotics Kits: Kits like LEGO Mindstorms and VEX Robotics allow beginners to build and program their own robots.

- Workshops and Camps: Robotics workshops and camps are available for students of all ages.

Career Opportunities

The robotics industry offers a wide range of career opportunities for individuals with skills in engineering, computer science, and related fields.

- Robotics Engineer: Designs, builds, and tests robots.

- Software Engineer: Develops software for robots and robotic systems.

- Mechanical Engineer: Designs and analyzes the mechanical components of robots.

- Electrical Engineer: Designs and develops the electrical systems of robots.

- AI/ML Engineer: Develops AI and machine learning algorithms for robots.

Conclusion

Robotics is a rapidly evolving field with the potential to transform industries and improve our lives. From manufacturing and healthcare to logistics and exploration, robots are already making a significant impact. As technology advances, we can expect to see even greater integration of robots into our world, raising both exciting opportunities and important ethical considerations. By understanding the fundamentals of robotics and exploring the available resources, individuals can position themselves to be part of this transformative field.